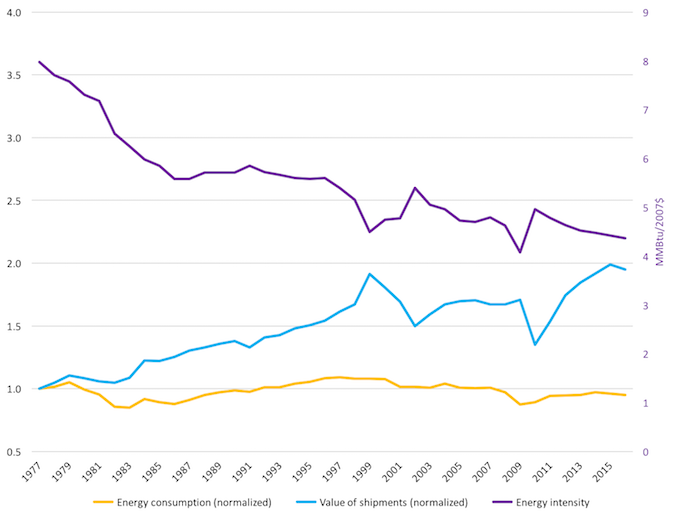

The industrial sector is unique among end-use sectors in that its energy intensity has declined consistently in recent decades, decreasing 45% from 1977 through 2016. The decline occurred even though the sector’s energy use has fluctuated, its output has almost doubled, and economic activity has risen and fallen with economic cycles.

This trend is promising because the industrial sector accounted for slightly more than 30% of the US gross domestic product in 2016. The sector also comprises dozens of individual industries spanning agriculture, forestry, fisheries, construction, mining, and manufacturing.

Industrial energy consumption, value of shipments, and energy intensity, 1977–2016

The graph represents a composite of these industries. (Graphing data for individual industries is impractical because of shifting definitions, numbers, diversity, and business cycles.) For the industrial sector as a whole, an inverse relationship exists between intensity and value of shipments. When utilization of capacity increases, intensity decreases. (“Value of shipments” measures the economic value of all products shipped from industrial plants in an industry.)

Some of this change results from structural shifts in the industrial sector, but much of it can be attributed to technology and practice improvements in energy-intensive industries, which account for more than four-fifths of the sector’s energy use. For example, the steel industry has made major modernization investments that resulted in a 28% reduction in Btus per ton of steel produced between 1990 and 2004. A large factor in this improvement has been a shift toward more reliance on secondary steel (recycled steel) and less reliance on primary steel (from iron ore through a reduction process). Importantly, this shift from primary to secondary product was enabled by the development of technology that allows the use of scrap to produce high-strength steel alloys.

Also contributing to reduced industrial energy use are system approaches, such as combined heat and power (CHP). CHP is an energy-efficient method of generating both electricity and useful thermal energy in a single, integrated system that is used in many energy intensive industries. A CHP system saves energy by recovering heat from power-only generation that would otherwise be wasted and using it to satisfy on-site thermal energy needs. The chemical industry has reduced energy use per unit of product by about 40% since 1980 by expanding CHP installations and modernizing process technology.

As the adoption of new techniques, such as smart manufacturing and intelligent efficiency, continues, so should industrial energy intensity’s downward trend.

ACEEE began assembling this data for a 2007 research report. It has made regular updates as new data become available. For more national metrics on industrial energy efficiency, see The Long-Term Energy Efficiency Potential: What the Evidence Suggests and Energy Efficiency in the United States: 35 Years and Counting.

Data Points is a blog series focusing on the graphs and other images that tell the energy efficiency story.